Textile Additive Laminating Machine

Contacts: Zhu Hua

Email: sales@hb-ah.com

WhatsApp:+8613373666051

Address:Taihu Road, Langxi Economic Development Zone, Xuancheng, Anhui, China

Video display of processed products

Product performance and characteristics

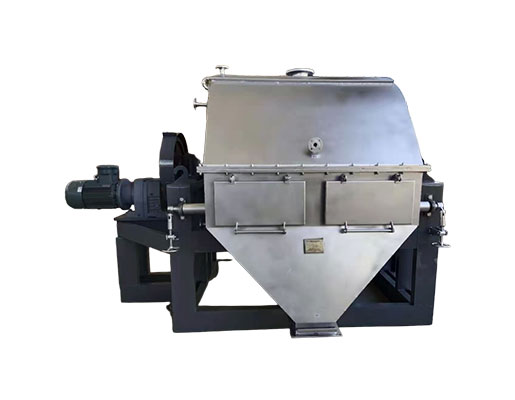

1, There are 2 ways of distributing, including upper distributing and rear feeding. Based on the characteristics of chemical materials, there are single drum type and double drum type.

2,The trough insulation is provided with steam insulation, heat transfer oil circulation insulation and electric heating heat transfer oil insulation

3,The equipment is divided into open type and semi-closed type, fully enclosed type, vacuum type and nitrogen protection type.

4,Blade materials include brass, tin bronze, steel plate, nylon, bakelite, phenolic resin and alloy hacksaw blade.

5,The discharging system has single outlet, double outlet and storage outlet.

6,Special requirements: the regular shape and size of the material can ensure the thickness and size uniformity of the material.

7,The cooling or (heating) system has split jacket type or spray type and special spoiler technology. It is designed according to the size and specification of the slicer and the characteristics of the material, which can improve the heat exchange efficiency, increase the strength of the rotating drum, and increase the output of the relative products. Through actual measurement, it can be increased by 0.3 to 1 time compared with the general conventional tablet machine.

8,Rotating joint is adopted for cooling water, which can reliably prevent water leakage, and new process is applied to reduce the consumption of cooling water.

9,Both ends of the drum are provided with thermal insulation layers and side scrapers, and there is no binding at both ends of the drum, so there is no friction power consumption at both ends of the drum, and the problem of unstable startup due to end binding is eliminated.

1, Water inlet

2, Driving part

3, Drum turning

4, Cooling system

5, Water outlet system

6, Scraper system

7, Frame

8, Tray

Equipment characteristics

※ The performance reaches the level of modern foreign equipment

※ Side scraper is provided to avoid material accumulation at the side of drum

※ Compact equipment structure and small floor area

※ Half tube jacket tray, safe and reliable

※ Atomization cooling, good cooling effect

※ Stepless speed change, drum speed adjustable

※ High drum precision

※ Wide adaptability, easy and flexible operation

※ Use multiple groups of scrapers for flexible adjustment

※ Multi-functional, both flake and dry

Scope of application

Classification |

Example of applied material |

| Organic class of matter | Maleic anhydride, paraffin, bitumen, caprolactam, p-nitrochlorinated benzene, catechol, p-dichlorobenzene, trimellitic anhydride, methoxy, 1,8-diamino naphthalene, diamino diphenylmethylmethane, N-phenylmaleimide, trimethylpropane, polyethylene glycol, polyethylene wax, polyvinyl acetate TMP、 Polyformaldehyde, dodecyl stearic acid, triphenyl ester phosphate (TPP), MS, chloromethane, etc. |

| Inorganic type | Sulfur, alkali sulfide, white block, aluminum sulfate, calcium chloride, caustic soda, sodium sulfhydrate, etc. |

| Fine chemical industry | NA, 4020, RD, DTPD and other anti-aging agents; Aflux、Aktiplest、Z-80、 Plasticizer A, Plasticizer B and other plasticizers, RC series organic cobalt salt MOCA、Leather treatment auxiliary, surfactant, plastic auxiliary, rubber auxiliary, organic palladium salt, protective wax, etc. |

| Grease chemical industry | Stearic acids and their salts, fatty acids (alcohols) and their salts, glycerides DMP-100、 Rosin grease, palm oil, etc. |

| Resin type | PF resin, tackifier resin, terpene dilute resin, rosin resin, phenolic resin, polymeric rosin, epoxy resin, polyamide resin, petroleum resin C5-C9. |

| Other | Hot melt adhesive, emulsion explosive, gelatin, beeswax, sodium fluosilicate, thermoset molding compound, rubber and plastic materials, relief tank bottom materials, electronic grade materials MDA、DTPT、 Nitrocellulose fertilizer, nitrogen based compound fertilizer, PP/high concentration compound fertilizer, etc. |

Service items: Provide users with standard scale or special specifications of drum flaker (drier) as required.

Specifications |

Drum specification (mm) |

Motor power (KW) |

Slicing speed (r/min) |

Reference overall dimension (mm) |

||

Frequency conversion control |

L |

W |

H |

|||

| DZ-1 | 400×500 | 2.2-3 | 2.5-12 | 1400 | 800 | 1200 |

| DZ-2 | 600×600 | 2.2-3 | 2.5-12 | 1550 | 1000 | 1400 |

| DZ-3 | 600×800 | 3-4 | 2.5-12 | 1750 | 1000 | 1600 |

| DZ-4 | 800×1000 | 4-5.5 | 2.5-12 | 1920 | 1200 | 1800 |

| DZ-5 | 800×1200 | 4-5.5 | 2.5-12 | 2200 | 1200 | 1800 |

| DZ-6 | 1000×1000 | 4-5.5 | 2.5-12 | 1950 | 1400 | 2000 |

| DZ-7 | 1200×1200 | 5.5-7.5 | 2.5-12 | 2200 | 1600 | 2200 |

| DZ-8 | 1200×1500 | 5.5-7.5 | 2.5-12 | 2600 | 1600 | 2200 |

| DZ-9 | 1500×1500 | 5.5-7.5 | 2.5-12 | 2600 | 1900 | 2500 |

| DZ-10 | 1600×1800 | 7.5-11 | 2.5-12 | 3000 | 2000 | 2600 |

| DZ-11 | 1600×2500 | 11-15 | 2.5-12 | 4200 | 2100 | 2600 |

| DZ-12 | 2000×2000 | 11-15 | 2.5-12 | 3700 | 2500 | 2900 |

| DZ-13 | 2500×2000 | 15-21 | 2.5-12 | 3700 | 3000 | 3400 |

| DZ-14 | 1900×3000 | 15-21 | 2.5-12 | 4700 | 2400 | 2800 |

Display of processed product images

Presentation of recommended products

Send Inquiry